Why PP PPH-MM90 is Revolutionizing the Plastic Industry: Performance, Quality, and Versatility

Markets & Prices

Feb 28, 2025

719

1. What is PP PPH-MM90?

PP PPH-MM90 is a high-performance polypropylene (PP) material produced by Hengli Petrochemical. It has high transparency, high fluidity and good heat resistance, and is suitable for injection molding process. It is widely used in food packaging, home appliances (transparent panels), medical supplies (disposable syringes, drug packaging), daily necessities (transparent storage boxes, cosmetic packaging), etc.

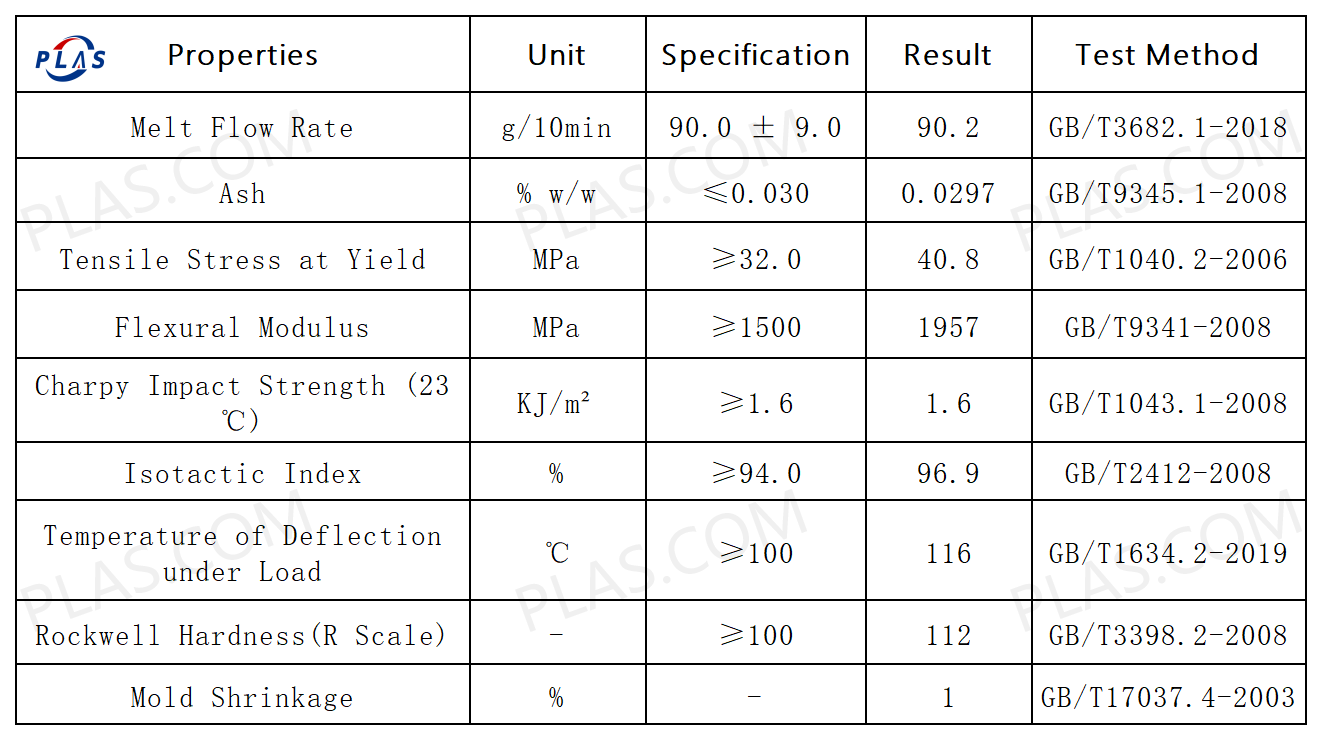

2. Physical properties

Synthesis process

Its production process involves polymerizing propylene monomer (C3H6), and converting gaseous propylene into solid polymers through catalysts and specific processes. Let's look at its chemical synthesis process step by step:

2.1 Raw material preparation

Propylene (C3H6): comes from petroleum or natural gas cracking. High-purity propylene is required as a monomer.

Catalyst: Ziegler-Natta catalyst or metallocene catalyst is commonly used. PP PPH-MM90 mostly uses Ziegler-Natta catalytic system to improve crystallinity and mechanical properties.

Co-catalyst: such as triethylaluminum (TEA) or methylaluminoxane (MAO), used to enhance the activity of the catalyst.

2.2 Polymerization (propylene polymerization)

In the polymerization reactor, propylene gas is pressurized and polymerized under the action of the catalyst. The temperature is usually maintained at 60-80°C and the pressure is 2-3MPa.

Propylene undergoes addition reaction through the active sites on the catalyst to form long-chain polypropylene molecules.

Chemical reaction equation:

2.3 Polymer separation and post-treatment

The solid polypropylene particles after polymerization are separated from the reactor, and the catalyst and unreacted monomers are removed.

In order to improve the performance of the material, additives may be mixed, such as antioxidants, UV stabilizers, processing aids, etc.

2.4 Granulation and packaging

The molten polypropylene is granulated by an extruder to form uniform PP PPH-MM90 resin particles.

Finally, it is cooled, dried and packaged, ready to be supplied to injection molding and plastic processing companies.

This production process ensures that PP PPH-MM90 has excellent melt flowability, rigidity, heat resistance and dimensional stability, which is very suitable for thin-wall injection molding applications.

3. Application fields

Food packaging: transparent food containers, beverage cups, fresh-keeping boxes, etc.

Home appliances: transparent panels, control knobs and other parts.

Medical supplies: disposable syringes, drug packaging, etc.

Daily necessities: transparent storage boxes, cosmetic packaging, etc.

4. Market situation

From the perspective of the global polypropylene market, the market size is estimated to be US$123.46 billion in 2022, and the annual compound growth rate is expected to be 4.7% between 2023 and 2030. This shows that the demand for polypropylene products is growing steadily.

PP PPH-MM90, as Hengli Petrochemical's main polypropylene product, has a stable market price and broad application prospects. As a global leading integrated refining and chemical enterprise, Hengli Petrochemical's business covers refining, petrochemicals, polyester new materials and textiles. The polypropylene products it produces have stable quality and are widely used in the production of various plastic products, with a stable market share.

Disclaimer

1. The above remarks only represent the author’s own opinions and do not represent the position of this site;

2. When reprinting articles, please indicate that they are from "Plas.com (www.plas.com)" and include the author’s name. Commercial use requires authorization from the author and the website;

3. If there is any infringement, please contact the author directly, or send a written letter to our company for transmission and processing;

Latest News

20231228 | CrudeOil Price

BEIOUYI: China’s first polyolefin elastomer (POE) industrial equipment is put into production

BASF and BYD will jointly build a new materials factory

Contact Us

Get App

Top