Material Comparison

Product Info

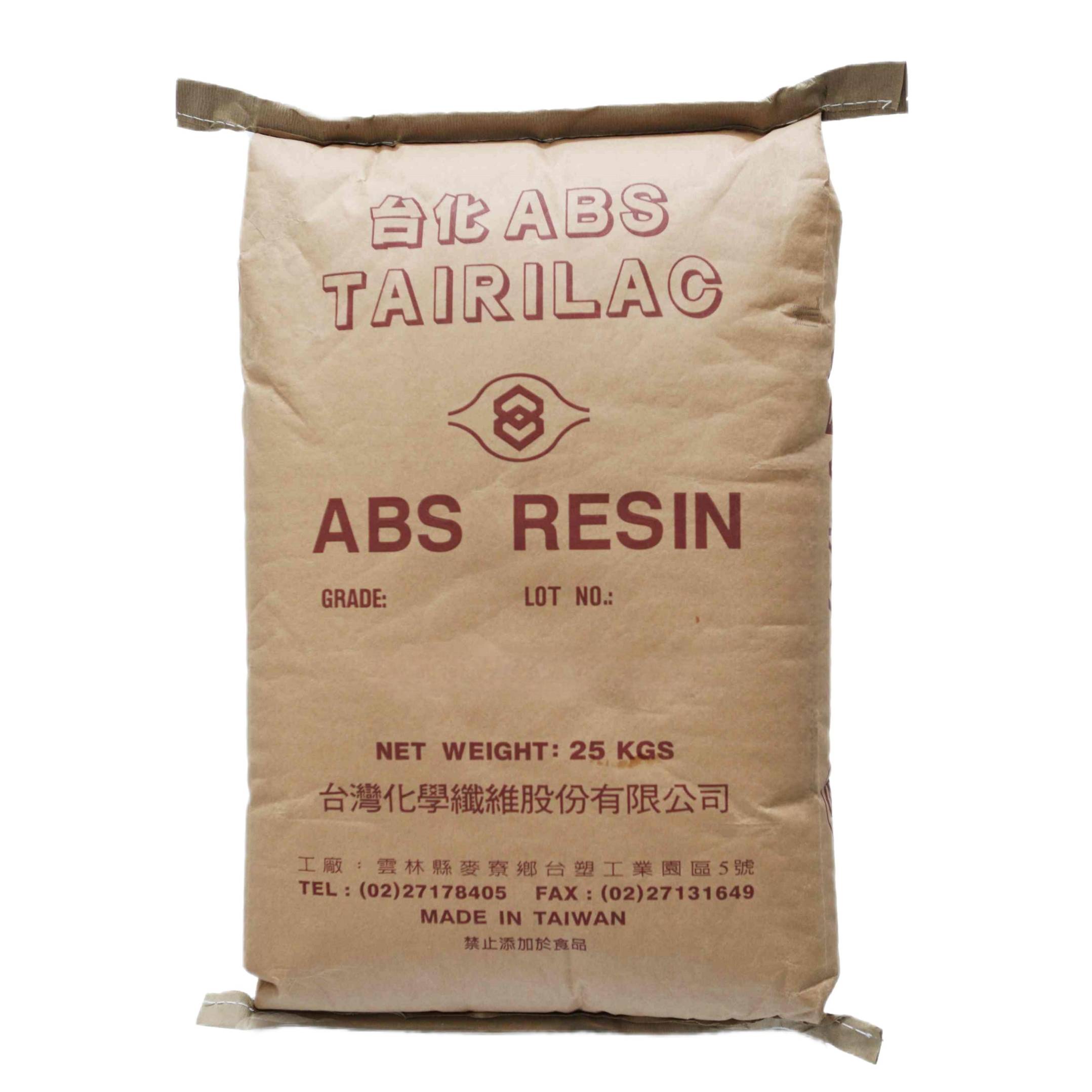

Product Name

Brand Name

Usages

Properties

Certificates

ABS AG1000 FCFC TAIWAN

TAIRILAC®

ABS pipe、Helmet、safety helmet、Pipe fittings、Footwear

High impact resistance、Characteristics: Ultra hi

UL

FDA

MSDS

TDS

Processing

MSDS

UL

RoHS

SVHC

Environmental

--

--

--

--

--

--

--

--

--

--

--

--

--

--

--

Plastic Datasheets

Physical Properties

Test Condition

Test Method

Unit

ABS/FCFC TAIWAN/AG1000

Density

ASTMD792

g/cm³

1

Density

23°C

ISO1183

g/cm³

1

Melt Mass-Flow Rate

200°C/5.0kg

ASTMD1238

g/10min

0

Melt Mass-Flow Rate

220°C/10.0kg

ASTMD1238

g/10min

1

Melt Mass-Flow Rate

200°C/5.0kg

ISO1133

g/10min

0

Melt Mass-Flow Rate

220°C/10.0kg

ISO1133

g/10min

1

Modeling Shrinkage

MD

内部方法

%

0

Mechanical Properties

Test Condition

Test Method

Unit

ABS/FCFC TAIWAN/AG1000

Tensile Strength

23°C

ASTMD638

Mpa

3

Tensile Stress

屈服,23°C

ISO527-2

Mpa

3

Flexural Modulus

23°C

ASTMD790

Mpa

1

Flexural Modulus

23°C

ISO178

Mpa

1

Flexural Strength

23°C

ASTMD790

Mpa

5

Flexural Stress

23°C

ISO178

Mpa

5

Thermal Properties

Test Condition

Test Method

Unit

ABS/FCFC TAIWAN/AG1000

Deflection Temperature Under Load?

1.8MPa,未退火,12.7mm

ASTMD648

°C

8

Deflection Temperature Under Load?

1.8MPa,Unannealed,12.7mm

ISO75-2/A

°C

8

Deflection Temperature Under Load?

1.8MPa,Annealed

ASTMD648

°C

9

Deflection Temperature Under Load?

1.8MPa,退火

ISO75-2/A

°C

9

Vicat Softening Temperature

ASTMD15253

°C

9

Vicat Softening Temperature

ISO306/A

°C

9

Impact Properties

Test Condition

Test Method

Unit

ABS/FCFC TAIWAN/AG1000

Notched Izod Impact Strength

23°C,6.35mm

ISO180

J/m

3

Notched Izod Impact Strength

23°C,6.35mm

ASTMD256

J/m

3