Material Comparison

Product Info

Product Name

Brand Name

Usages

Properties

Certificates

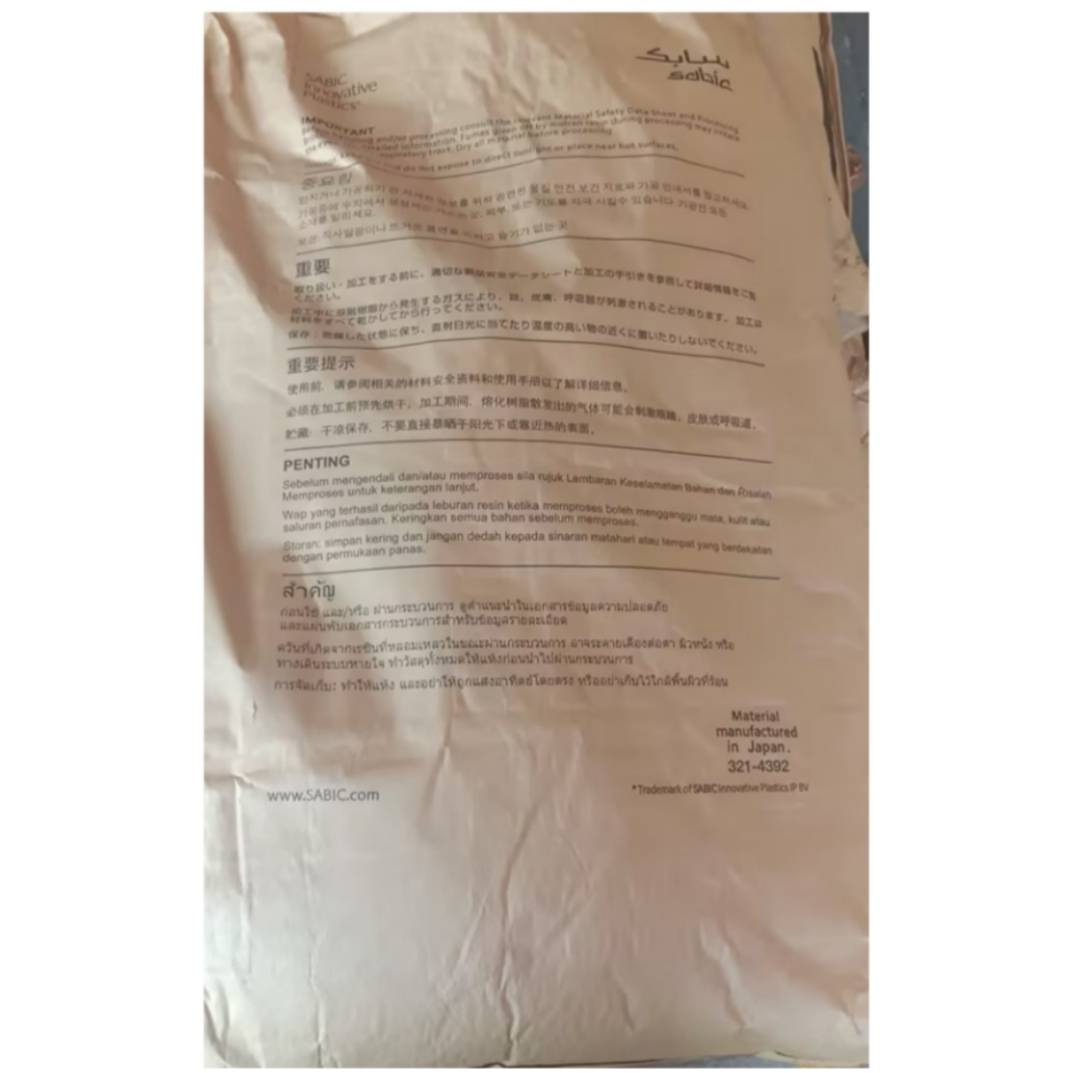

PEI EX99689C 基础创新塑料(美国)

--

电气电子应用、汽车部件

玻纤增强、润滑

--

--

--

--

--

--

--

--

--

--

--

--

--

--

--

Plastic Datasheets

Thermal Properties

Test Condition

Test Method

Unit

PEI/基础创新塑料(美国)/EX99689C

Linear thermal expansion coefficient

TD:-40到40°C

ISO11359-2

cm/cm/°C

3

Linear thermal expansion coefficient

TD:-40到40°C

ASTME831

cm/cm/°C

3

Linear thermal expansion coefficient

MD:-40到40°C

ISO11359-2

cm/cm/°C

3

Heat Deflection Temperature

1.8MPa,未退火,3.20mm

ASTMD648

°C

2

Heat Deflection Temperature

1.8MPa,未退火,64.0mm跨距

ISO75-2/Af

°C

2

Linear thermal expansion coefficient

MD:-40到40°C

ASTME831

cm/cm/°C

3

Physical

Test Condition

Test Method

Unit

PEI/基础创新塑料(美国)/EX99689C

Moisture Absorption

平衡,23°C,50%RH

ISO62

%

0

Moisture Absorption

24hr,50%RH

ASTMD570

%

0

Modeling Shrinkage

MD:24小时

ASTMD955

%

0

Modeling Shrinkage

TD:24hr

ASTMD955

%

0

Modeling Shrinkage

TD:24小时

ISO294-4

%

0

Modeling Shrinkage

MD:24小时

ISO294-4

%

0

Mechanical Properties

Test Condition

Test Method

Unit

PEI/基础创新塑料(美国)/EX99689C

Flexural Modulus

50.0mm跨距

ASTMD790

Mpa

8

Flexural Modulus

ISO178

Mpa

7

Tensile Elongation

断裂

ASTMD638

%

1

Flexural Strength

ASTMD790

Mpa

2

Tensile Modulus

ISO527-2/1

Mpa

1

Tensile Strain

断裂

ISO527-2

%

1

Tensile Stress

断裂

ISO527-2

Mpa

1

Flexural Stress

ISO178

Mpa

2

Tensile Modulus

ASTMD638

Mpa

1

Tensile Strength

断裂

ASTMD638

Mpa

1

Impact Properties

Test Condition

Test Method

Unit

PEI/基础创新塑料(美国)/EX99689C

Unnotched Izod Impact Strength

23°C

ISO180/1U

kJ/m²

2

Instrumented Dart Impact

23°C,EnergyatPeakLoad

ASTMD3763

J

1

Multi-Axial Instrumented Impact Energy

ISO6603-2

J

2

Notched Izod Impact Strength

23°C

ISO180/1A

kJ/m²

5

Flammability

Test Condition

Test Method

Unit

PEI/基础创新塑料(美国)/EX99689C

Flame Rating

0.35mm,TestingbySABIC

UL94

V

Electrical Properties

Test Condition

Test Method

Unit

PEI/基础创新塑料(美国)/EX99689C

Surface Resistivity

ASTMD257

ohms

1

Contact Us

Get App

Top