Material Comparison

Product Info

Product Name

Brand Name

Usages

Properties

Certificates

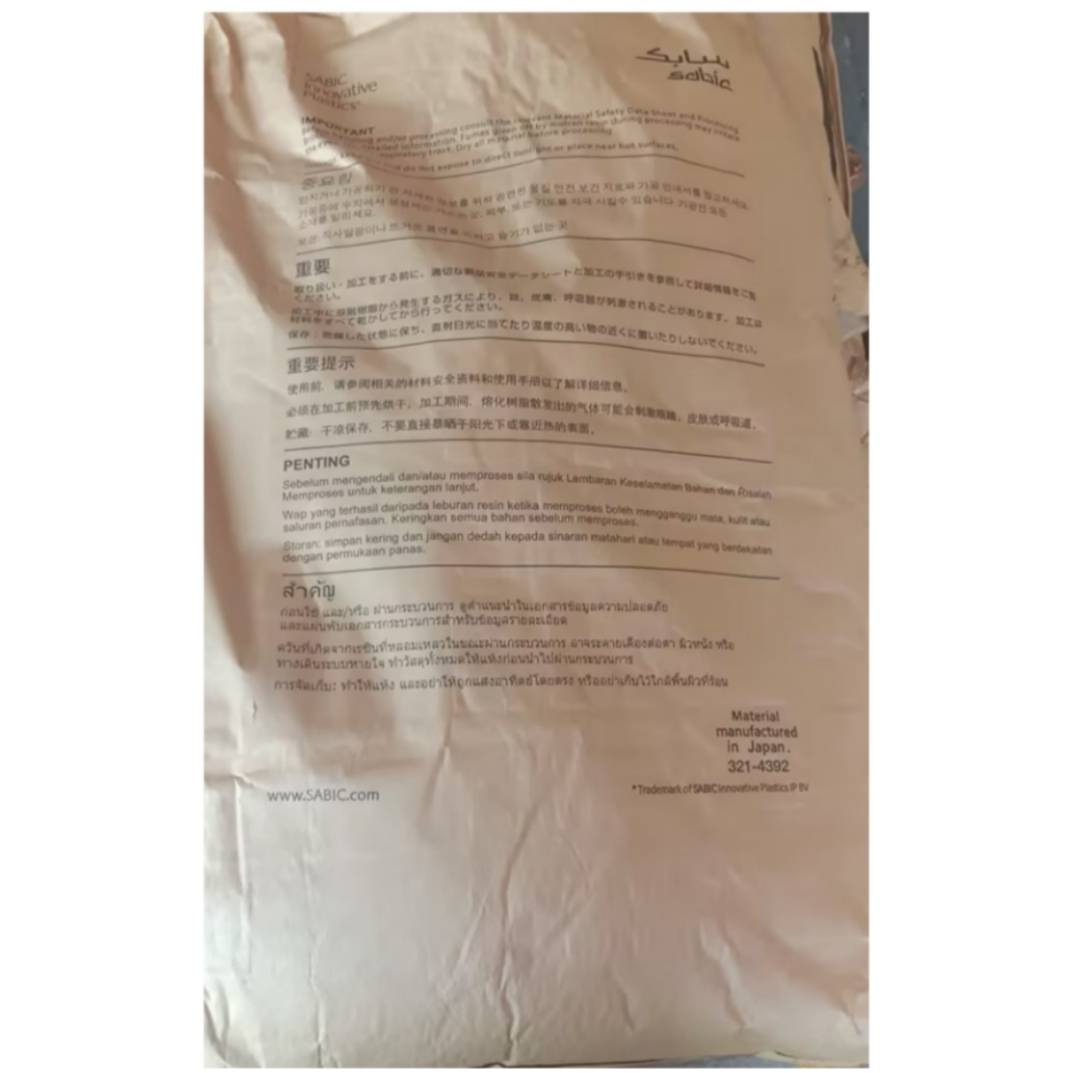

PEI ATX100 BK1343M SABIC INNOVATIVE US

ULTEM™

Electronic and electrical、Automotive components、Handbags, containers, mov

Thermal stability、High temperature resistan、Acceptable food contact,

--

--

--

--

--

--

--

--

--

--

--

--

--

--

--

Plastic Datasheets

Mechanical performance

Test Condition

Test Method

Unit

PEI/SABIC INNOVATIVE US/ATX100 BK1343M

Elmendorf Tear Strength (MD)

50um,Blown Film

g

340

A

Elmendorf Tear Strength (TD)

50um,Blown Film

g

280

A

Secant modulus-

50um,Blown Film

MPa

130

A

Tensile fracture strength

Compression Molded

MPa

18

A

Tensile strength at break (MD)

50um,Blown Film

MPa

28

A

Tensile fracture strength (TD)

50um,Blown Film

MPa

26

A

Tensile elongation at break (MD)

50um,Blown Film

%

280

A

Falling hammer impact

50um,Blown Film

g

210

A

Processing performance

Test Condition

Test Method

Unit

PEI/SABIC INNOVATIVE US/ATX100 BK1343M

Adapter temperature

℃

210-225

Basic performance

Test Condition

Test Method

Unit

PEI/SABIC INNOVATIVE US/ATX100 BK1343M

density

g/cm³

0.922

A

Melt mass flow rate

190℃/2.16kg

g/10min

0.12

A