Material Comparison

Product Info

Product Name

Brand Name

Usages

Properties

Certificates

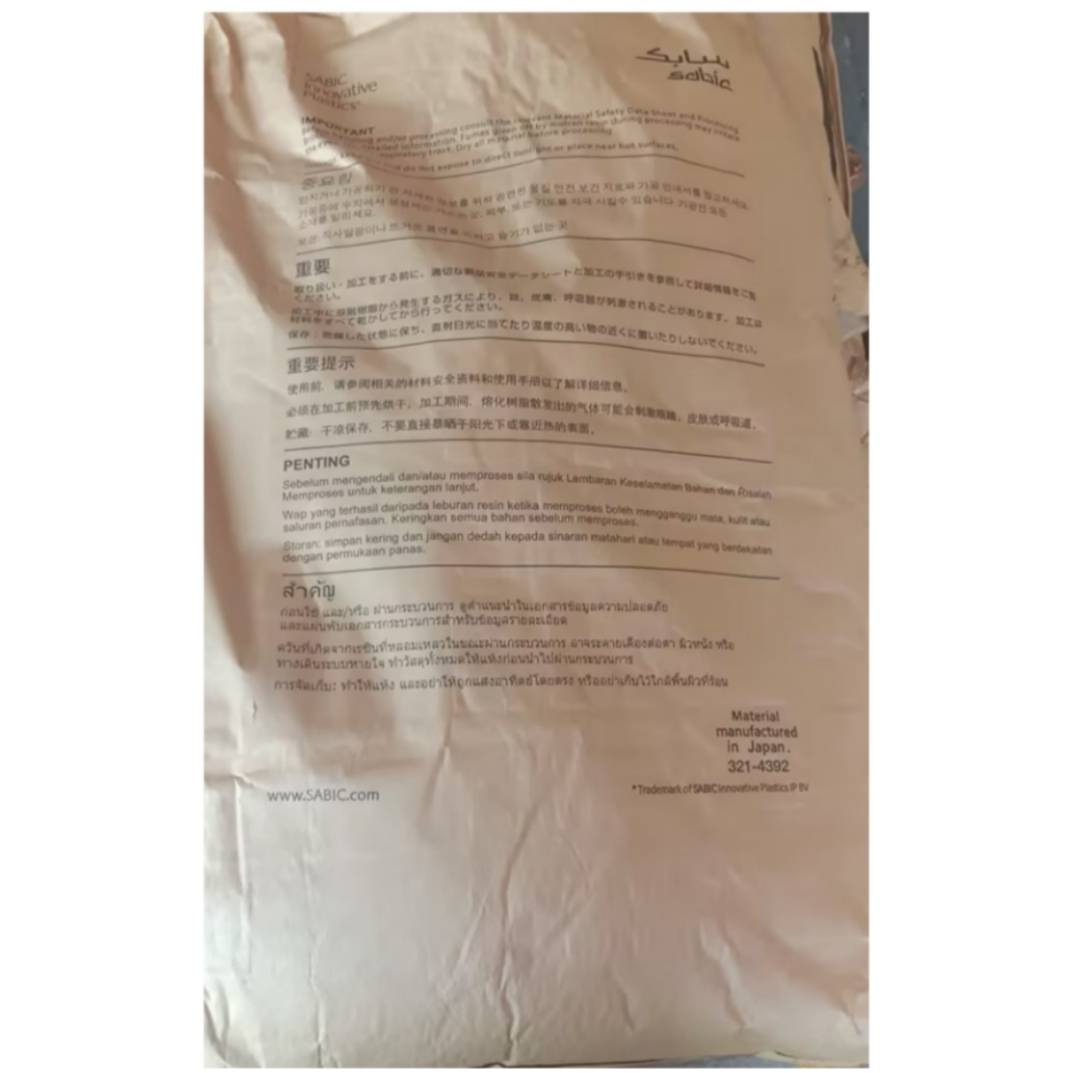

PEI 2100BK SABIC INNOVATIVE US

ULTEM™

Fiber grade、plug、Washer、Connector、Fatigue relief supplies

Glass fiber reinforced、wear resistant、High rigidity、Thermal stability、Flame retardant、High impact resistance、Filler: Glass fiber reinf、10% filler by weight、10% filler by weight

--

--

--

--

--

--

--

--

--

--

--

--

--

--

--

Plastic Datasheets

physical property

Test Condition

Test Method

Unit

PEI/SABIC INNOVATIVE US/2100BK

Density/specific gravity

ASTMD792

g/cm³

1

Melt mass flow rate

337°C/6.6kg

ASTMD1238

g/10min

7

Shrinkage rate

MD:3.20mm

内部方法

%

0

Water absorption rate

24hr

ASTMD570

%

0

Water absorption rate

平衡,23°C

ASTMD570

%

1

Mechanical performance

Test Condition

Test Method

Unit

PEI/SABIC INNOVATIVE US/2100BK

Flexural Strength4

Break,100mmSpan

ASTMD790

Mpa

2

Tensile strength 3

屈服

ASTMD638

Mpa

1

Tensile strength 3

断裂

ASTMD638

Mpa

1

Tensile modulus 2

ASTMD638

Mpa

4

Elongation rate 4

断裂

ASTMD638

%

6

Bending modulus 4

100mmSpan

ASTMD790

Mpa

5

Thermal performance

Test Condition

Test Method

Unit

PEI/SABIC INNOVATIVE US/2100BK

RTIElec

UL746

°C

1

Evolution Calendar intelligent importer

UL746

°C

1

RTIStr

UL746

°C

1

Hot deformation temperature

0.45MPa,未退火,6.40mm

ASTMD648

°C

2

Hot deformation temperature

1.8MPa,未退火,6.40mm

ASTMD648

°C

2

Vicat softening temperature

ASTMD15255

°C

2

Linear coefficient of thermal expansion

MD:-20to150°C

ASTME831

cm/cm/°C

3

Electrical performance

Test Condition

Test Method

Unit

PEI/SABIC INNOVATIVE US/2100BK

Dielectric strength

1.60mm,inOil

ASTMD149

KV/mm

2

Volume resistivity

ASTMD257

ohms·cm

1

Impact performance

Test Condition

Test Method

Unit

PEI/SABIC INNOVATIVE US/2100BK

ReverseNotchIzodImpact

3.20mm

ASTMD256

J/m

4

Impact strength of cantilever beam gap

23°C

ASTMD256

J/m

5

Impact strength of cantilever beam gap

23°C

ASTMD4812

J/m

4

flammability

Test Condition

Test Method

Unit

PEI/SABIC INNOVATIVE US/2100BK

Extreme Oxygen Index

ASTMD2863

%

4