Material Comparison

Product Info

Product Name

Brand Name

Usages

Properties

Certificates

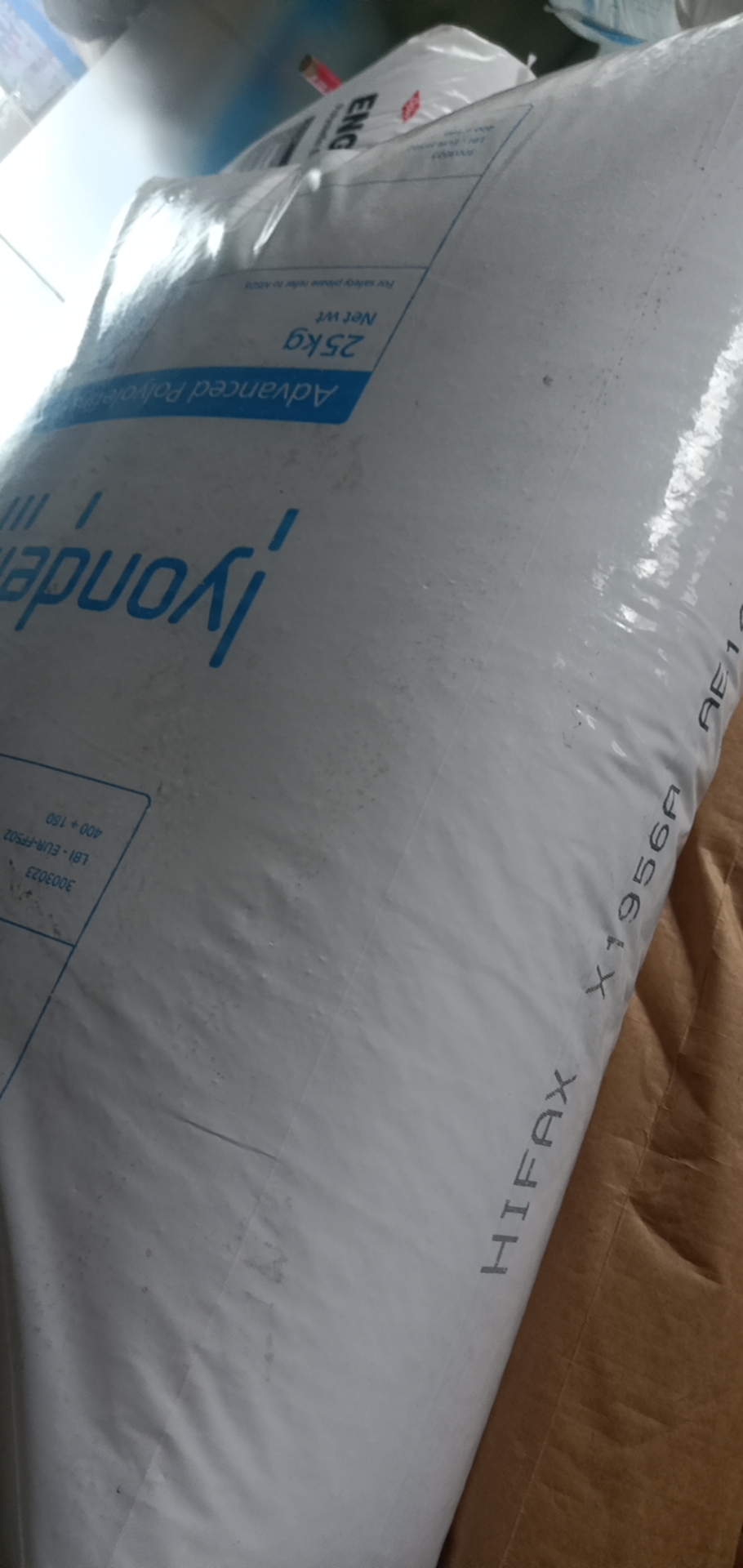

TPO X1956A LYONDELLBASELL HOLAND

Hifax

--

--

--

--

--

--

--

--

--

--

--

--

--

--

--

--

--

Plastic Datasheets

physical property

Test Condition

Test Method

Unit

TPO/LYONDELLBASELL HOLAND/X1956A

Melt Mass Flow Rate (MFR) 230 ° C/2.16 kg

/

ISO 1133

g/10min

0

Mechanical performance

Test Condition

Test Method

Unit

TPO/LYONDELLBASELL HOLAND/X1956A

Tensile strength fracture (brk)

/

ISO 527-1/-2

Mpa

3

Tensile strength yield (yld)

/

ISO 527-1/-2

Mpa

2

Tensile elongation fracture (brk)

/

ISO 527-1/-2

%

5

Tensile elongation yield (yld)

/

ISO 527-1/-2

%

1

tear strength

/

ASTM D 624

kN/m

6

Bending modulus

/

ISO 178

Mpa

8

Impact performance

Test Condition

Test Method

Unit

TPO/LYONDELLBASELL HOLAND/X1956A

Cantilever beam notch (Izod -40 ℃ (-40 ℉))

/

ISO 179

kJ/m²

5

Izod Unnotched -20 ℃ (-4 ℉)

/

ISO 179

kJ/m²

1

Izod Unnotched at 23 ℃ (73 ℉)

/

ISO 179

kJ/m²

9

Thermal Properties

Test Condition

Test Method

Unit

TPO/LYONDELLBASELL HOLAND/X1956A

Vicat softening temperature

ISO 306/A50

°C

1

Relative Temperature Index (RTI) intensity w/o impact-

DSC

UL 746B

°C

7

hardness

Test Condition

Test Method

Unit

TPO/LYONDELLBASELL HOLAND/X1956A

Shore hardness D

15 sec

ISO 868

D

5

optical performance

Test Condition

Test Method

Unit

TPO/LYONDELLBASELL HOLAND/X1956A

gloss

60°, 45 m

ASTM D 2457

mm

5