Material Comparison

Product Info

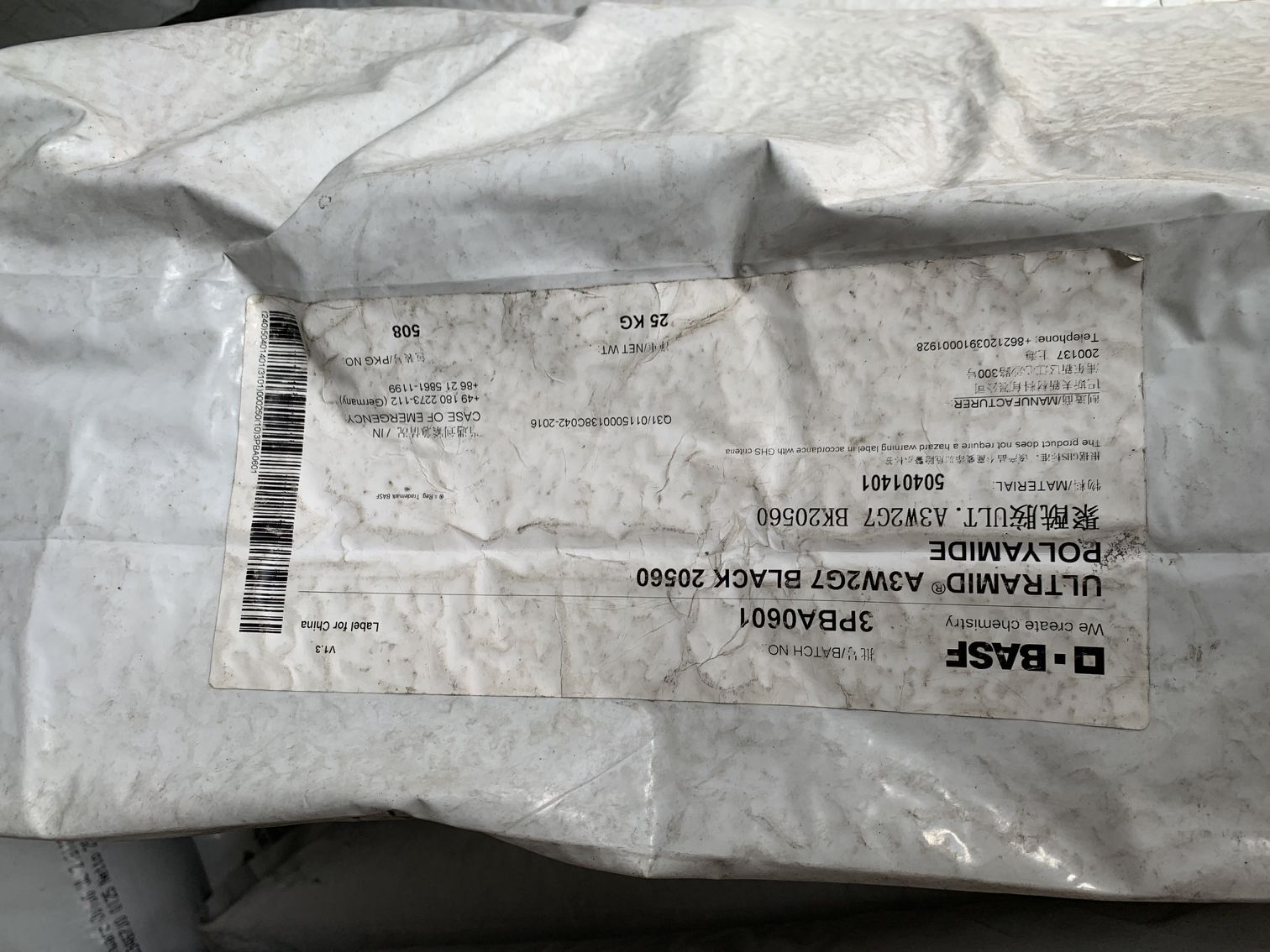

Product Name

Brand Name

Usages

Properties

Certificates

PA66 A3W2G7 BK20560 BASF SHANGHAI

Ultramid®

Powertrain、Air cooler

35% filler by weight、Filler: Glass fiber reinf、Heat resistance、Oil resistant

--

--

--

--

--

--

--

--

--

--

--

--

--

--

--

Plastic Datasheets

physical property

Test Condition

Test Method

Unit

PA66/BASF SHANGHAI/A3W2G7 BK20560

Shrinkage rate

MD2.0mm

ISO294-4

%

0

Shrinkage rate

TD2.0mm

ISO294-4

%

0

Mechanical performance

Test Condition

Test Method

Unit

PA66/BASF SHANGHAI/A3W2G7 BK20560

elongation at break

23°C

ISO527-2

%

3

Charpy Notched Impact Strength

23°C

ISO179/1eA

kJ/m²

1

Charpy Notched Impact Strength

-30°C

ISO179/1eA

kJ/m²

1

Impact strength of simply supported beam without notch

23°C

ISO179/1eU

kJ/m²

9

Impact strength of simply supported beam without notch

-30°C

ISO179/1eU

kJ/m²

8

Tensile modulus

23°C

ISO527-2

Mpa

1

tensile strength

23°C

ISO527-2

Mpa

2

Bending modulus

23°C

ISO178

Mpa

1

Impact strength of cantilever beam gap

23°C

ISO180/1A

kJ/m²

1

Impact strength of cantilever beam gap

-30°C

ISO180/1A

kJ/m²

1

Thermal performance

Test Condition

Test Method

Unit

PA66/BASF SHANGHAI/A3W2G7 BK20560

Hot deformation temperature

1.80MPa退火

ISO75-2/Af

°C

2